Daily Safety Checklist For Gantry Crane Operators

hndfcranedg

2021-08-07

Share

Safety technical rules

- There should be a certain understanding of the crane special personnel to operate the crane.

- The side of the main beam of the crane gantry must be hung with the lifting capacity and the manufacturer's sign.

- When the crane is working, no one is allowed to stay on the crane or trolley.

- When crane inspection or maintenance, the crane must be powered off.

- When the crane is running without load, the hook must be lifted at least above the height of the obstacle on the running route.

- When the crane is running with heavy load, the heavy load must be lifted at least 0.5m above the obstacle on the running line.

- It is forbidden to throw down objects from the crane by any method.

- Tools and equipment must be stored in a special box, forbidden to be scattered randomly on a large car or cart to avoid falling.

- Strictly prohibit lifting heavy objects overhead.

- It is forbidden to transport or lift people by hook or on the lifting weight.

- When lifting liquid metals or harmful liquids and important articles, no matter how much they weigh. Must first micro-lift 200mn from the ground, verify that the brake is reliable after lifting.

- Prohibit the storage of flammable materials (such as kerosene, etc.) on the crane.

- In the beginning of the use of 12 months, the crane must be carried out regular safety and technical inspection, in addition to careful inspection of the crane's cut parts. Load test should also be carried out.

- Only special personnel are allowed to serve as the crane electrical maintenance work.

- If the conductive parts and bare wires of the casing or protective cover is not complete. Then do not allow the use of equipment.

- repair must be used in the voltage of 36 volts or less portable lighting.

- When 1 must work with electricity, to wear on rubber gloves. Wear rubber shoes and use tools with insulated handles, in addition, there should be a person to watch the main power switch, in case of danger immediately cut off the power.

- All metal parts on the motor, electrical equipment and electrical enclosure, which may conduct electricity, must be grounded.

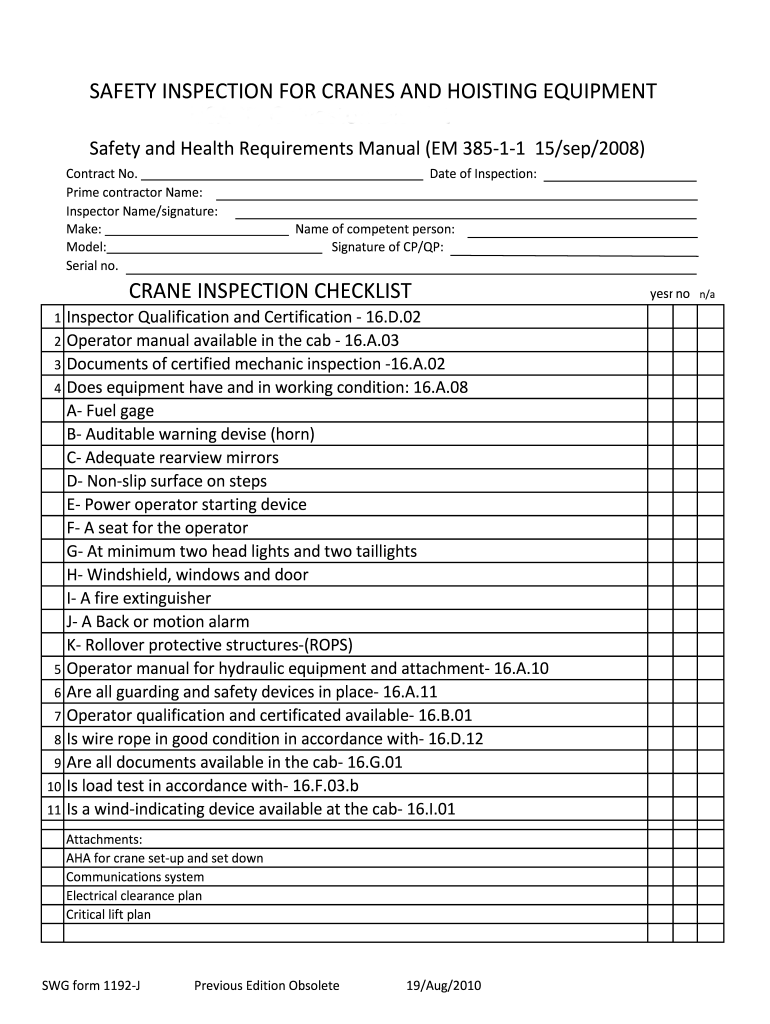

Gantry crane daily checklist

Driver duties

- Familiar with the use of the crane, performance, operation and maintenance rules.

- Strictly abide by the safety and technical rules.

- The crane should do before starting operation.

- Understand the power supply situation, whether there is a temporary power failure maintenance situation.

- The crane must be monitored with the total knife switch disconnected, check the connection and use of important parts, and make necessary adjustments to individual mechanisms.

- No tools or other items shall be left on the crane to avoid personal accidents or damage to machinery and equipment in the course of work.

- Add lubricating grease to each lubrication point of the equipment according to regulations.

- For cranes working in the open air, open their fixtures first and then operate them.

- Before the main switch is connected to the power, the driver must turn all controller handles to zero. And the control room to go to the platform of the warehouse cover and the end of the beam door closed.

- Before each start of the crane, must issue a driving warning signal (electric bell) must be aware of the lifting of the lifting weight shall not exceed the rated lifting weight.

- The driver must work closely with the lifting work, moving and lifting heavy objects, should only listen to the signal issued by the hooker, but the stop signal, regardless of who issued, should be immediately stopped.

- lifting heavy objects, must be in a vertical position, do not allow the use of mobile trolley or trolley to drag heavy objects or tilt lifting.

- The size of the crane must run at the slowest speed close to the limit position.

- The crane's controller should be turned on gradually. Before the machinery completely stops running, it is forbidden to reverse the controller from the down position directly to the reverse position for braking, but it can be used to prevent accidents from happening.

- The driver should ensure that the crane to prevent the crane in another crane collision, in the case of a crane failure, before allowing the crane to push the crane, in this case, both cranes are not allowed to lift heavy objects.

- In the case of a significant reduction in voltage and power interruption. The total knife switch must be disconnected, all the controllers turn to zero position.

- When the crane motor suddenly stops or line voltage drops sharply, all controllers are pulled to zero position as soon as possible. The main switch of the driver's room must be cut off. If there is a heavy load on the crane hook during a power failure, the driver and hooker should warn anyone not allowed to pass under the heavy load.

- When the crane lifts heavy objects or puts down the hook, the driver must not leave.

- When the crane work is completed, the spreader should be raised to a higher position, so that the controller is in the zero position, and cut off the total knife switch.

- After the work is finished, the driver must lock the total knife switch box.

- Clean and wipe the equipment, check the situation of each part again, and make necessary preparations for the next shift.

- After the work is finished, the driver will hand over the crane handover record book to the succeeding driver, and report the problems found in the crane operation to the relevant departments and the succeeding driver.

- When the driver leaves the crane, the crane must be parked on the prescribed stopping point.

Get A Quote

Related Products

Latest News

Browse Products

Free download

contact us

Operation Principle: customer orientation , excellent quality , interity-based and excellent service .

+86-18237383867copy

©2025 Henan Dafang Heavy Machine Co.,LtdPrivacy PolicySite Map