How To Choose a Overhead Crane Wheel Replacement

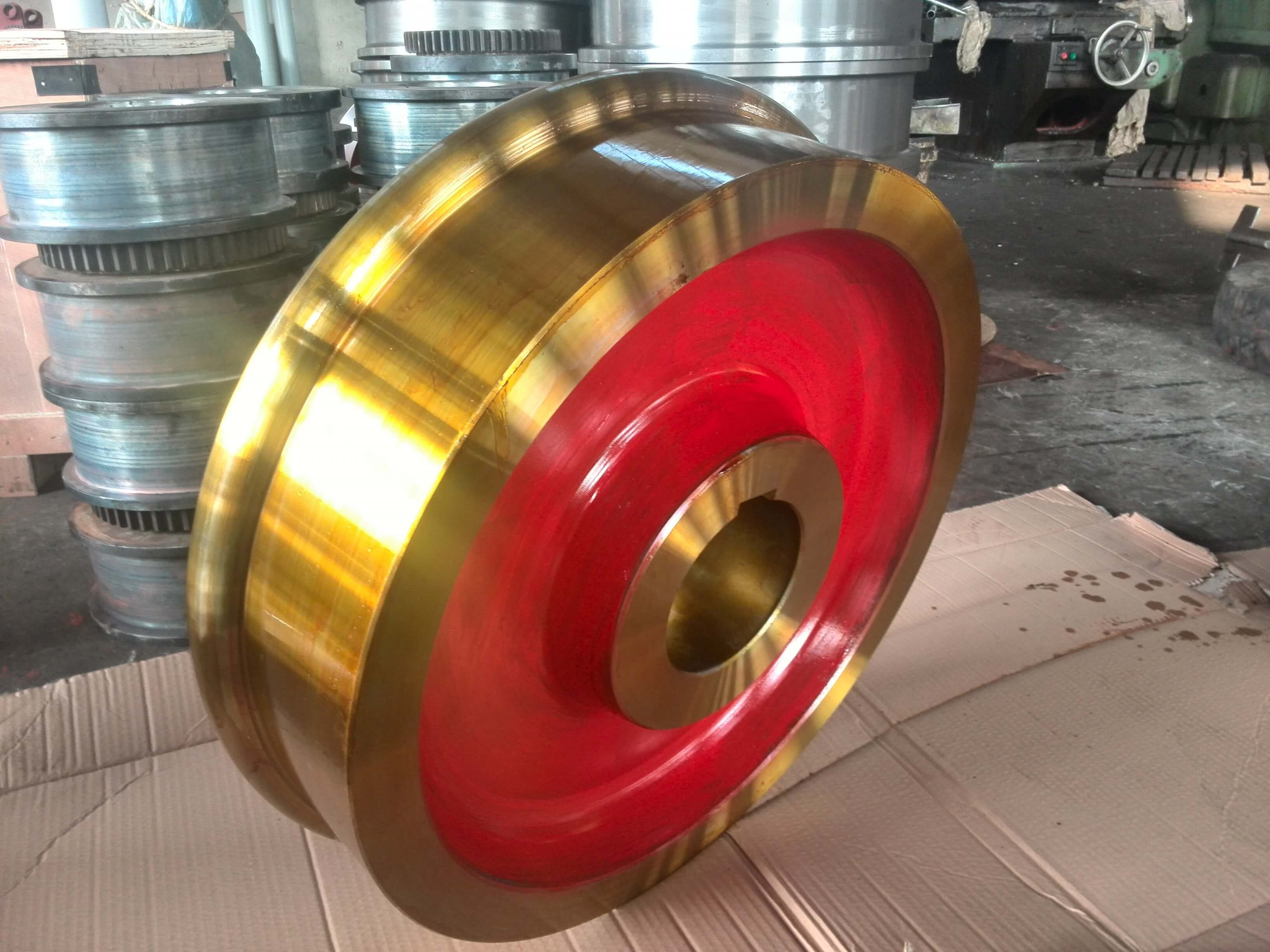

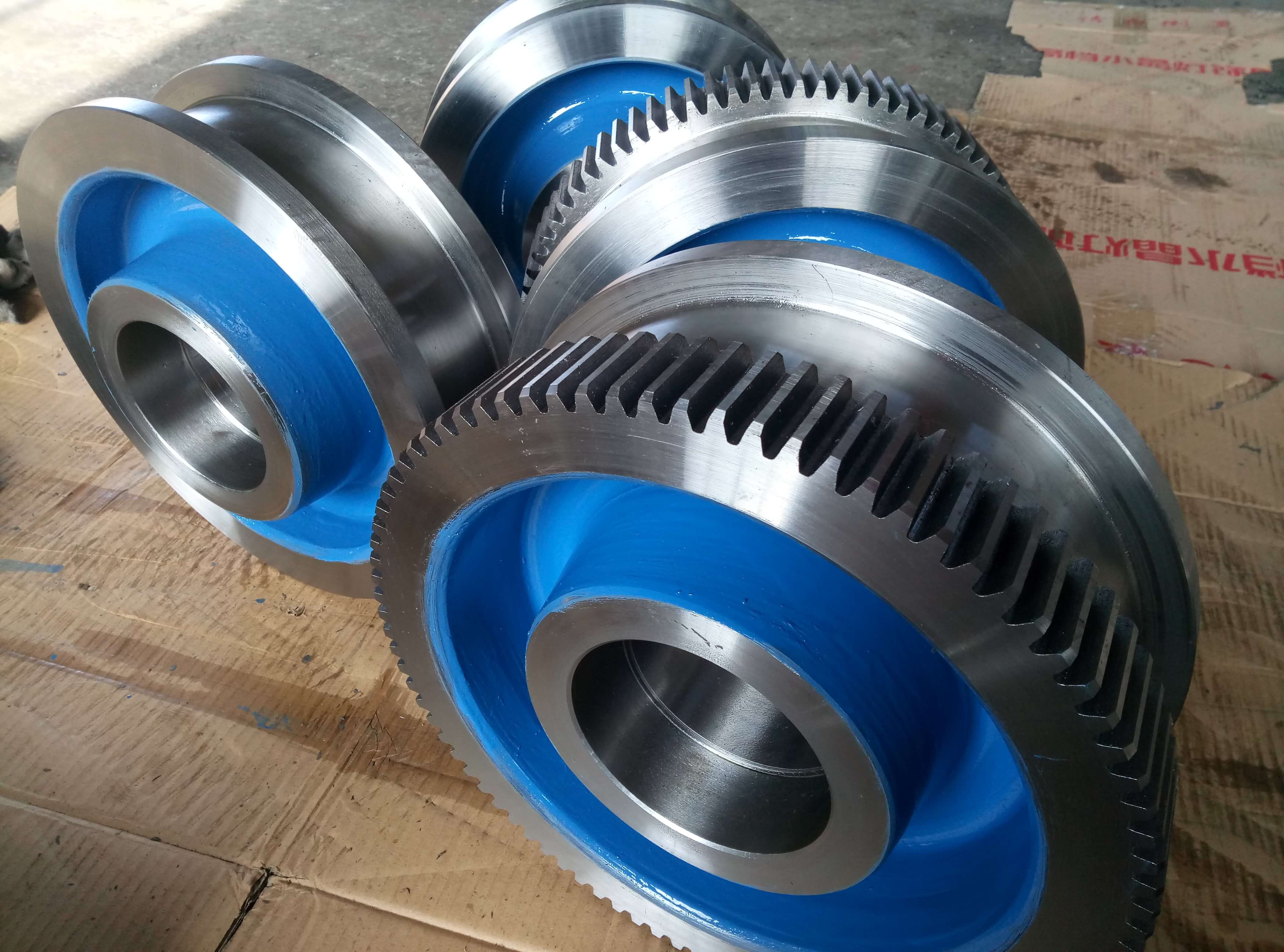

There are various classifications of wheels for overhead cranes, which can be classified by usage, with or without rim, by wheel tread, and by contact with the top of the track.

In the replacement of crane wheels to be selected in accordance with the provisions, then how to choose it? There are several tips to provide reference when replacing the wheel selection.

1.The longer the track, the poorer the straightness, the more likely to produce "wear track". Therefore, the wheel tread width should be wider than the width of the track.

- Conical car wheel tread width should be wider than the top surface of the track 30-40mm.

- Cylindrical car wheel tread width should be wider than the top surface of the track 25-35mm.

- Cylindrical trolley wheel tread width should be 15-20mm wider than the top surface of the track.

- Single rim wheel clearance of 5-10mm on one side.

2.To prevent the crane from derailment, the wheel rim height should be: 25-30mm for double rim wheels; 20-25mm for single rim wheels.

3.Centralized drive of the large span crane active wheels generally use conical wheels, passive wheels using cylindrical wheels, to a certain extent, can automatically correct the amount of crane deflection when running to prevent the crane to go tilt.

4.In order to reduce the wear of the wheel rim and extend the service life of the wheel, the rimless wheel can be used with the horizontal guide wheel to guide the operation of the horizontal wheel instead of rim-guided operation, which can change the sliding friction between the wheel rim and the side of the track to rolling friction between the horizontal wheel and the side of the track, reducing the running resistance and improving the life of the wheel.

5.Conical wheels are generally used on the running mechanism with two active wheels and two passive wheels.

6.The size of the wheel diameter depends on the size of the wheel pressure load (wheel pressure on the track), and the wheel pressure load is limited by the bearing capacity of the track foundation. When the crane is running on the track supported by sleepers, generally the permissible wheel pressure load is 100-120kN; when running on the track supported by concrete foundation or steel structure directly, the permissible wheel pressure load can reach 600kN.

When the lifting capacity is slightly larger, the wheel pressure load can be reduced by increasing the wheel diameter.

When the lifting capacity is larger, the wheel pressure load is usually reduced by increasing the wheel diameter. In order to make the wheel pressure load of each wheel evenly distributed, take the even (balance) beam type support device.

For large cranes with a particularly large number of wheels, in order to shorten the arrangement length of the wheels, a double-track rail can be used.

7.Trolley running mechanism of the two active wheels wheel pressure load to be slightly greater than the wheel pressure load of the two passive wheels.

At the same time, the following taboos need to be noted when replacement overhead crane wheels:

- The conical wheel diameter of the large end can not be placed on the outer side of the track.

- The taper of the wheel tread is related to the radius of the top of the track, and the conical wheel cannot be used with a track top without curvature.

- The wheel should be free of jamming and deformation.

- The clearance between the wheel sweeping track plate and the top surface of the track should not be greater than 10mm.

- The wheel shall not have defects affecting the use of performance, and shall not have cracks, patch welding.

- The relative wear of the two active wheel diameters should not exceed 3/1000 of the diameter.

- When the running mechanism starts or brakes, the active wheel should not slip in general.

- The fixing bolts of the wheel angle bearing box must have anti-loosening measures.

Get A Quote

Related Products

Operation Principle: customer orientation , excellent quality , interity-based and excellent service .