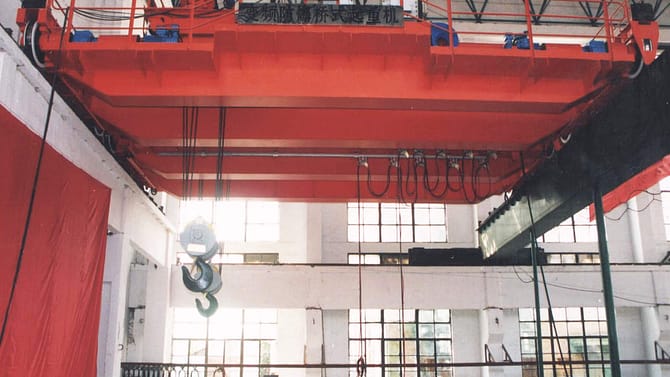

Product Introduction

Explosion proof overhead crane is one type of explosion-proof and hazardous environment overhead crane. All the motors and electrical equipment are explosion proof. The explosion proof level is in line with international standards and regulations. The lifting capacity of the explosion proof overhead crane is 5 to 100/30 tons and the working class is A4 and A5. Spark Resistant features available for all products.

The normal combustible environment include acetylene, hydrogen, ethylene, propane, metal dust, coal dust, cereal dust etc. If your work usage environment have any explosive air, our explosion proof cranes are dedicated for hazardous locations.

Application:

Explosion proof overhead crane is applied to sites, where is not higher than the II B or II C-class, and the sites with explosive air mixture formed with inflammable gas (or steam) and air whose factory ignition temperature groups of not less than the T4 group.

Features

- Compact structure, light, safe and reliable.

- High universality component, can be easily interchanged.

- Light dead weight, small in size, large lifting capacity.

- High safety and explosion-proof grade.

- The outside parts of hoist adopts no spark material, anti-explosion safely.

- Hoist exposed parts are all adopt special no-spark materials, reliable explosion-proof performance.

- Crane power supply method is cable but not bus bar.

- All wheels are stainless steel.

More Details

Hoist Explosion-proof Electric Box

Crane Travel Stainless Wheel

Explosion proof controller

Crane Explosion-proof Electric Box

Hoist Travel Stainless Wheel

Power supply method-cable

Client Care

You might be interested in the following questions

-

If your crane can work in the workshop where have any inflammable gas, dust?

Yes, because we will choose the suitable IP grade and Explosion proof motor, electric for you.

-

Whether you crane can explosion proof in our factory where has mixture of detonating gas?

Yes, due to your actual workshop, we will choose suitable explosion proof grade crane for you.

-

Whether you can offer customized crane?

Yep, of course, we are manufacturer, and we have our own engineer group. They can work out customized design according to your requirement. The most important thing is that you tell all the needed information.

-

What information shall we offer to get precise quotation & best design?

1. Lift Height:?

2. Span:?

3. Lift Capacity:?

4. Lift What:?

5. Indoor/outdoor?

6. Lift Speed: Single/Double/Variable?

7. Travel Speed: Single/Double/Variable?

8. Use Environment: Any explosive, combustible air? temperature?

9. Workshop practical situation? Drawing.

10. Use frequency? How many hours/day? How many times/hour? -

As for overhead crane, if the height from runway beam's surface to workshop's lowest point is too low, what special design can make?

- Different connection of main beam and end beam can reduce the height;

- Different crane design can shorten crane's self height.

-

Whether you can offer the matched spare parts?

Yep, as crane manufacturer, we offer all the related spare parts, such as motor, hoists, drums, wheels, grabs, hooks, rails, travel beams, enclosed bus bar etc.